Design, conception and making of

"Compliant swimming robotic fish" is the title of our project. So we needed a robot with the appearance of a fish, and capable of swimming thanks to a servomotor-actionned tail.

Material and Software

- 3D PRINTER

- Hard filament (Reprapper)

- Flexible filament (Ninjaflex)

- FreeCAD version, to conceive

- Simplify3D version, to prepare for printing

Conceiving and Printing a piece

-

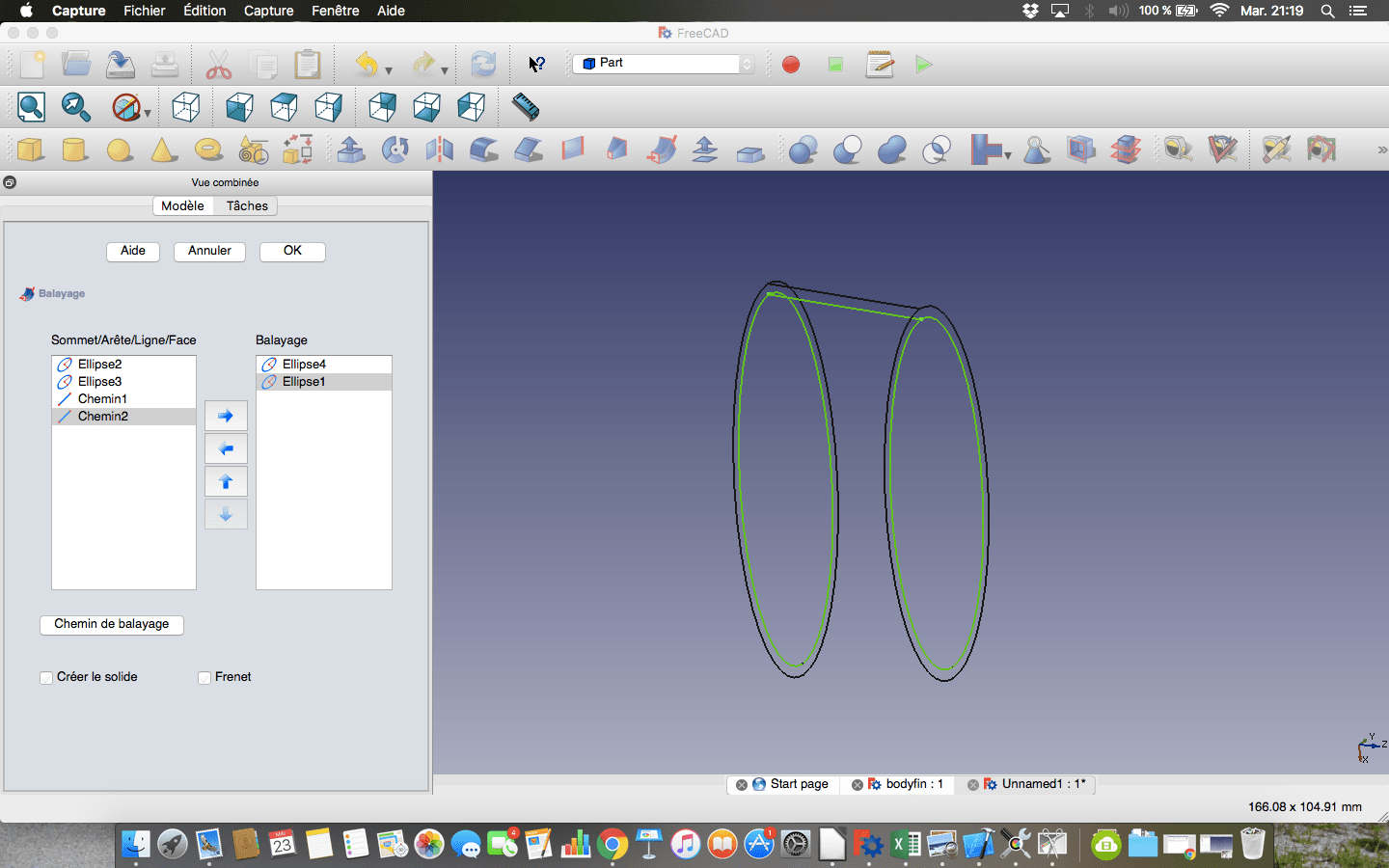

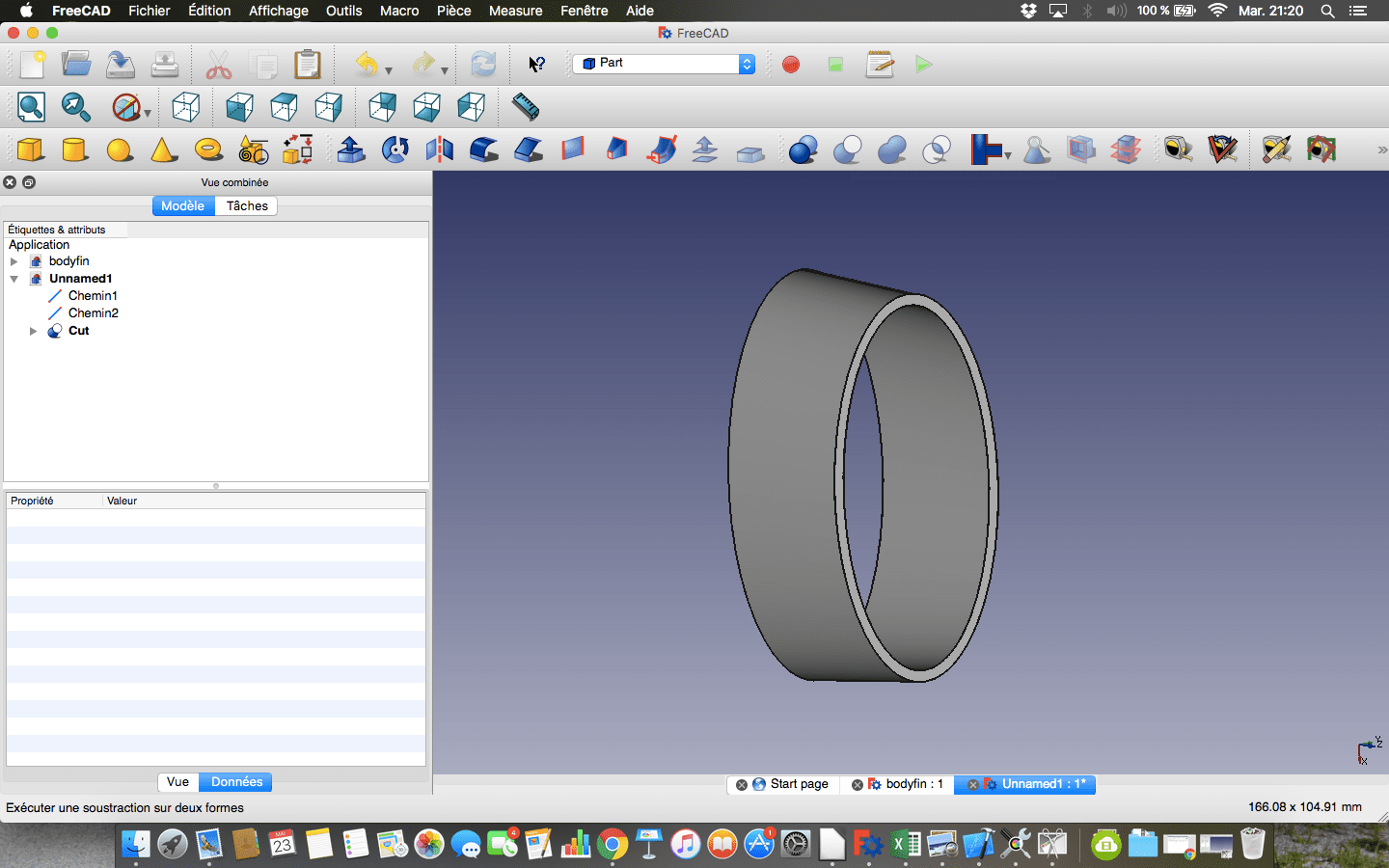

Conceiving on FreeCAD:

- The first thing to do is to design the lines of our future object, with precise sizes and dimensions.

- The next step is to start extruding those drawings (by using the Sweep tool) to get actual solids.

- Once we have the solids, we can for example use one to excavate the other and obtain the object we were looking for.

-

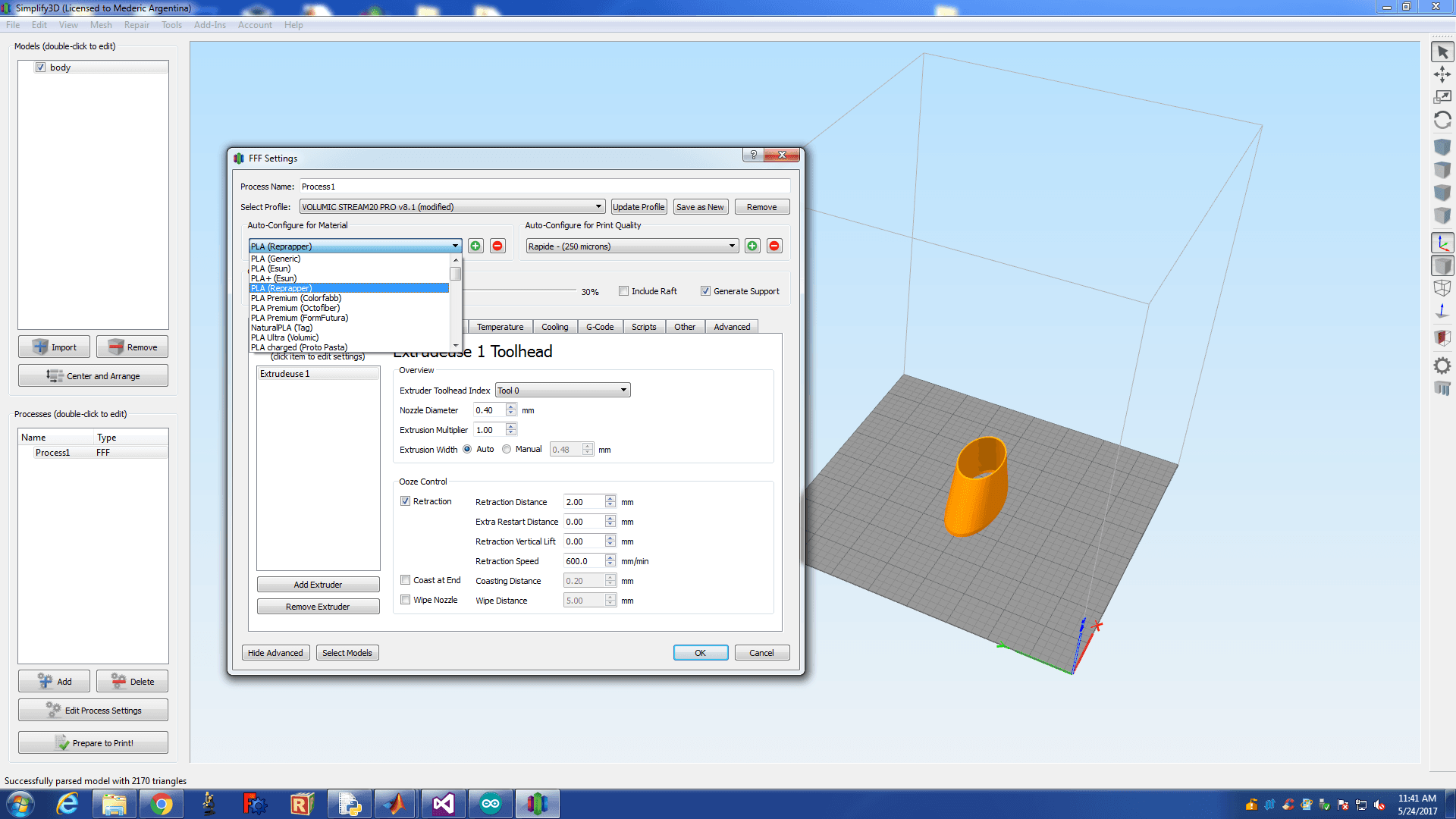

Prepare and print with Simplify3D:

- Import the .stl ("mesh file") on Simplify3D.

- Create a process, choosing the right filament and the right filling percentage (30% for example).

- Export on an SD card, put it in the 3D-Printer.

- Make sure the printer is loaded with the right filament, then launch the printing (30minutes ~ 2hours).

Robot composition

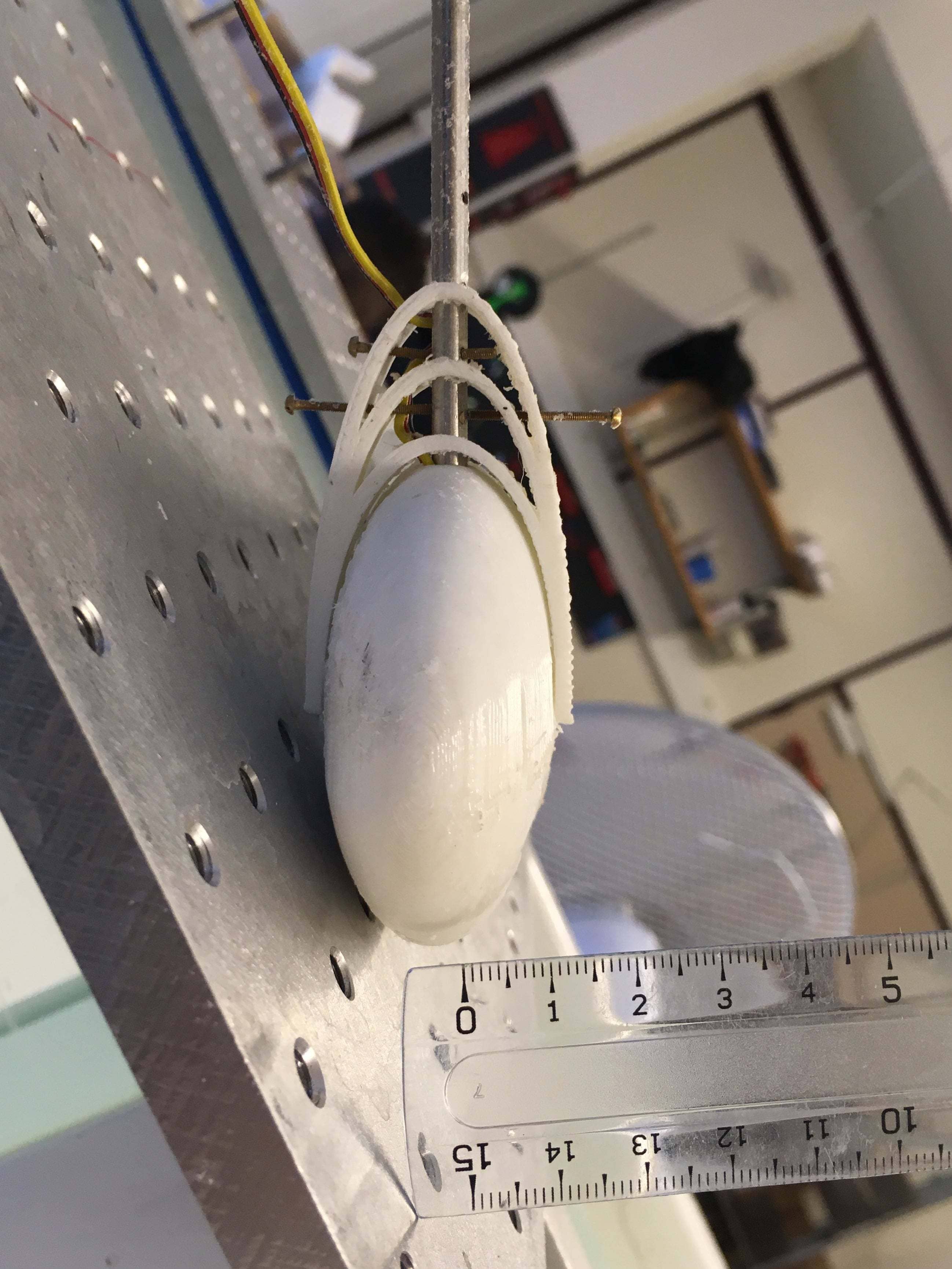

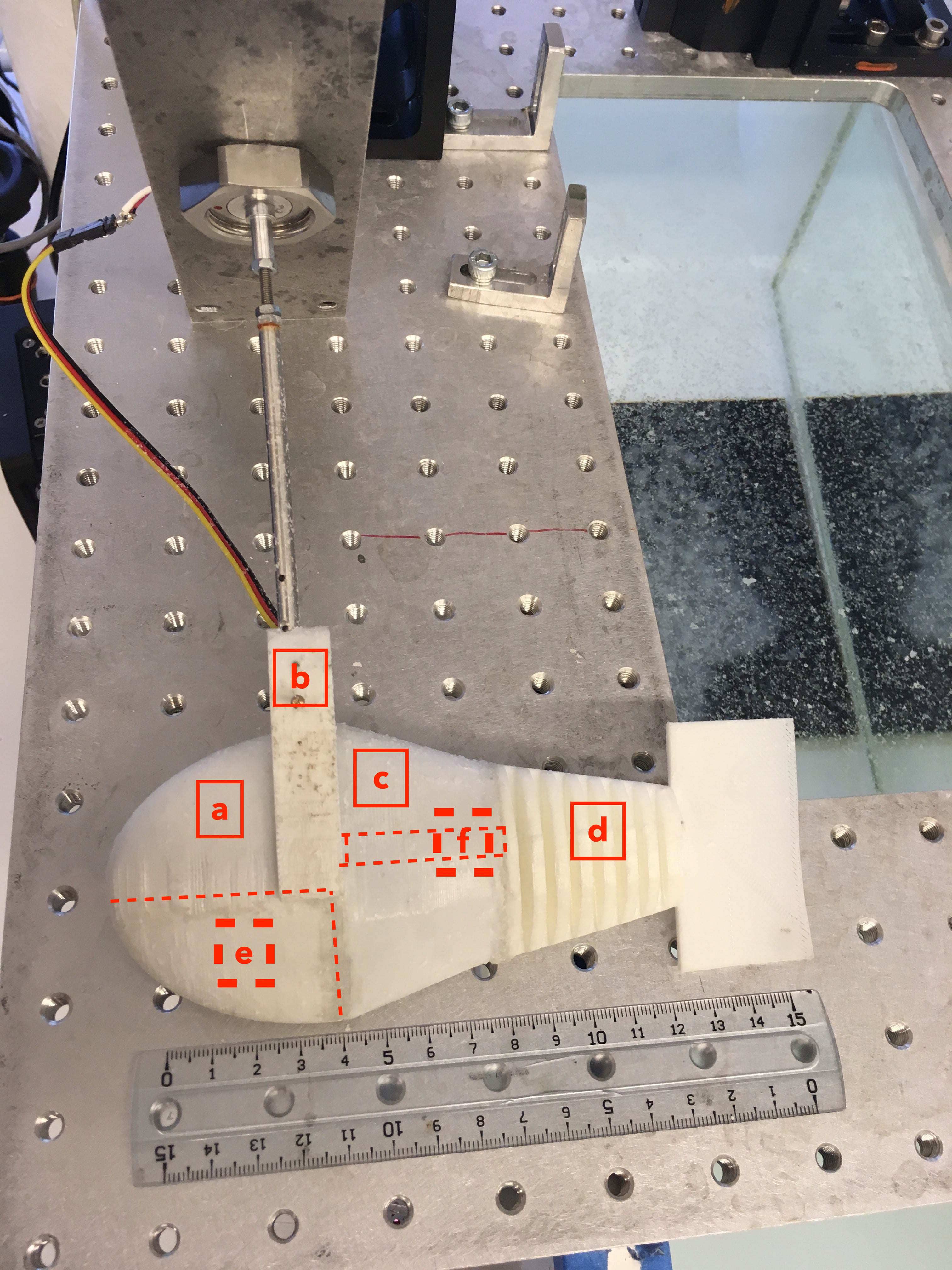

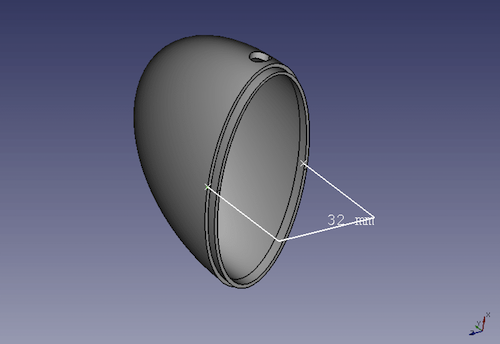

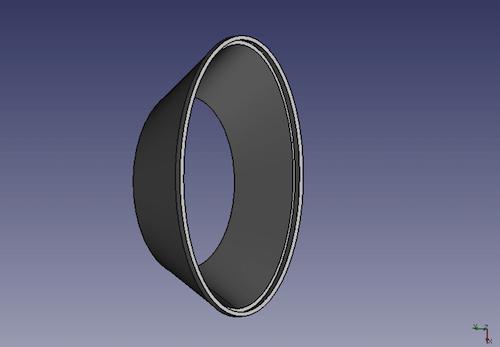

Our fish is composed of 6 essential parts :- The head [a] (soft),

- The rod's dock [b] (hard).

- The body [c] (soft),

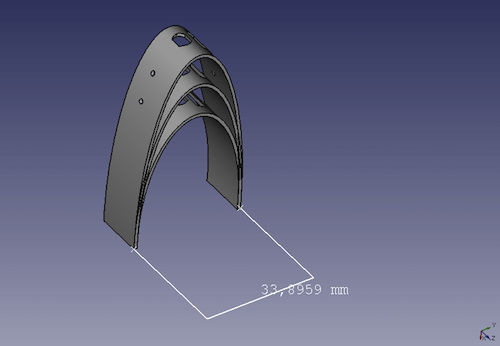

- The tail [d] (soft).

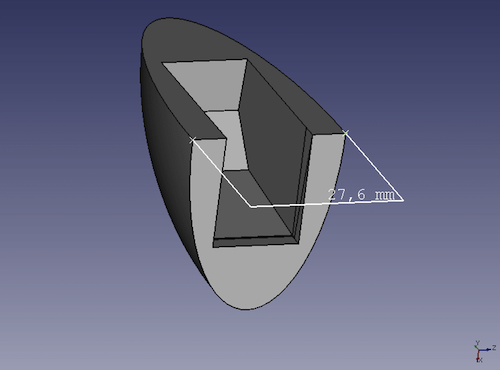

- The servomotor's dock [e] (hard), that goes inside the head,

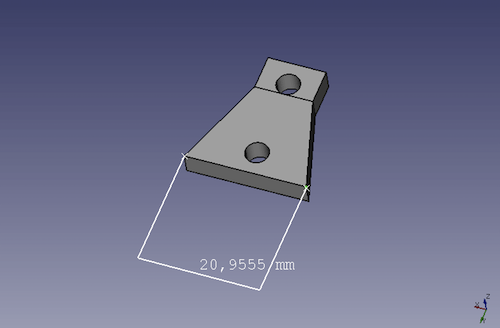

- The middle piece [f] (hard), which purpose is to fix the servomotor and the tail together,

- The servomotor.

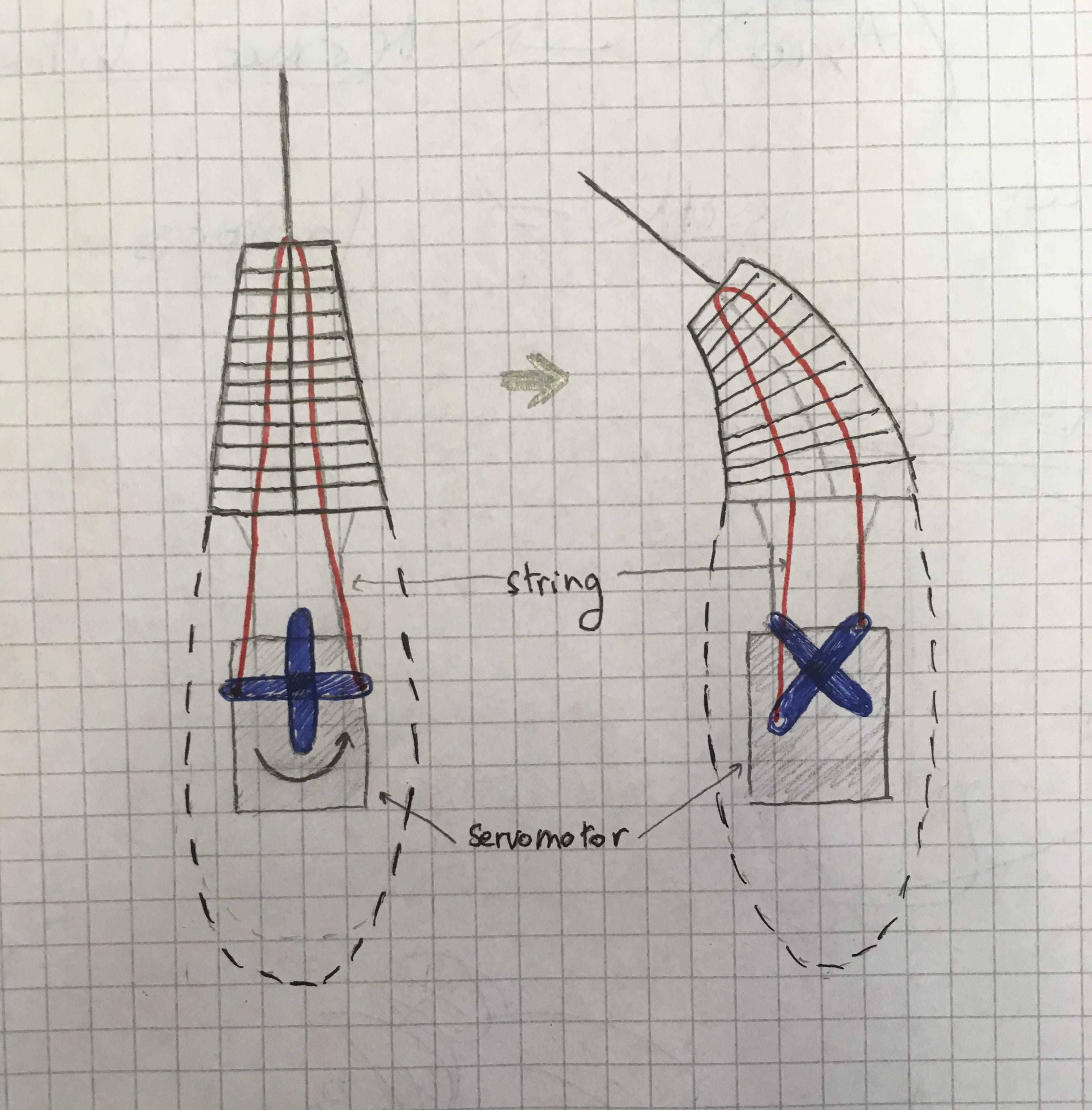

Concept and Tail

The way our fish works is actually pretty simple. There's a string running through the tail, and glued at the end of it. The 2 extremities of this string are linked to a cross-shaped solid is in cinjunction with the servomotor. When rotating, this cross pulls one extremity and pushes the other, making the tail move.